Products

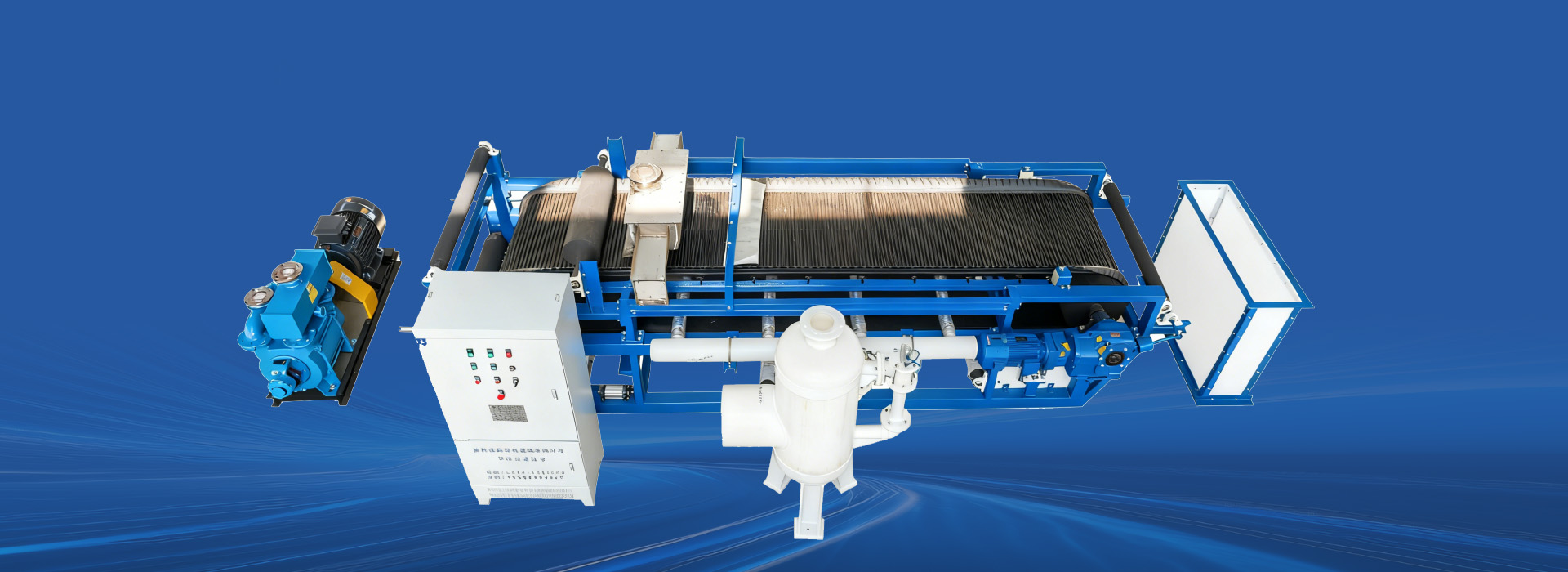

Huzhou Hejing specializes in solid-liquid separation equipmen

| Plate Size: | |

| Plate Material: | |

| Cloth Material: | |

| Filtration Pressure: | |

| Cake Discharging Method: | |

| Application: |

Product Details

Product Introduction:

A stainless steel vacuum belt filter is an industrial device that achieves solid-liquid separation through vacuum suction and gravity. The principle is same as DU series. But it’s frame is mainly made of stainless steel SS304 or SS316. Normally, with this machine, the vacuum pump will also adopts stainless steel, even the separators. Compared with conventional vacuum belt conveyors, it is easier to clean and has a longer service life.

Working Principle:

The slurry is evenly distributed onto a forward-moving filter cloth by the feeding device. Under the suction of the vacuum pump, the filtrate passes through the filter cloth and the filter belt's filtration holes into the vacuum chamber, and then flows into the filtrate tank through the connecting pipe at the bottom of the vacuum chamber. The solid phase is trapped on the filter cloth to form a filter cake. Because gravity and vacuum suction are in the same direction, larger particles settle below the filter cake, while smaller particles settle above it, forming a well-structured filter aid layer with low resistance and high filtration speed. The formed filter cake moves with the conveyor belt and is washed and dewatered multiple times before falling off at the filter cloth's turning point. Subsequently, the filter cloth and conveyor belt are separated by the drive roller and regenerated by high-pressure water washing. After being adjusted by the correction device, the filter cloth returns to the feeding end to start a new operating cycle.

Our Advantages:

1. Made of stainless steel (SS304 or SS316), corrosion resistant and long service life.

2. Easy to clean and maintain.

3. Fully automated continuous operation.

4. Filter cloth and belt are washed separately for high efficiency.

Applications:

Chemicals: acids, raw material pharmaceutical production, solvent recovery (e.g., boric acid, phosphoric acid, and various corrosive acids, alkalis, or salts).

Food: Liquid clarification, impurity removal (e.g., acetic acid, amylopectin derivatives, calcium citrate, calcium oxalate, calcium sulfate, sucrose glutamate, citric acid, lactic acid, maltose, proteins, vegetable oils, etc.).

Electronics & Photovoltaics: Chip manufacturing, thin film deposition.

Specifications:

|

Area (m²) |

Useful Width (mm) |

Useful Length (mm) |

Total Length (mm) |

Total Width (mm) |

Height (mm) |

Weight (ton) |

Vacuum Power (kw) |

Driving Power (kw) |

|

1 |

500 |

2000 |

4500 |

1150 |

1350 |

1.6 |

15 |

1.5 |

|

1.5 |

500 |

3000 |

5000 |

1150 |

1350 |

1.9 |

15 |

1.5 |

|

2 |

4000 |

6500 |

2.2 |

18.5 |

2.2 |

|||

|

2.5 |

5000 |

7200 |

2.7 |

18.5 |

2.2 |

|||

|

3 |

6000 |

9200 |

1.9 |

22 |

1.5 |

|||

|

4 |

630 |

6300 |

9100 |

1400 |

1850 |

3.6 |

30 |

2.2 |

|

5 |

8000 |

11000 |

4 |

37 |

2.2 |

|||

|

6 |

9500 |

12000 |

4.6 |

45 |

4 |

|||

|

8 |

12700 |

15500 |

5.2 |

45 |

4 |

|||

|

4 |

800 |

5000 |

8200 |

1550 |

2000 |

3.6 |

30 |

2.2 |

|

5 |

6000 |

9200 |

4 |

37 |

2.2 |

|||

|

5 |

1000 |

5000 |

8200 |

1750 |

2000 |

4 |

45 |

2.2 |

|

6 |

6000 |

9200 |

4.6 |

45 |

4 |

|||

|

7 |

7000 |

10200 |

4.8 |

45 |

4 |

|||

|

8 |

8000 |

11200 |

5.2 |

45 |

5.5 |

|||

|

10 |

10000 |

13200 |

5.9 |

55 |

5.5 |

|||

|

8 |

1300 |

6150 |

10600 |

2050 |

2000 |

5.2 |

45 |

4 |

|

10.4 |

8000 |

12600 |

6 |

55 |

5.5 |

|||

|

13 |

10000 |

14600 |

7 |

75 |

7.5 |

|||

|

15.6 |

12000 |

16600 |

8.5 |

75 |

7.5 |

|||

|

18.2 |

14000 |

18600 |

9.2 |

75 |

11 |

|||

|

20.8 |

16000 |

20600 |

11 |

90 |

15 |

|||

|

14.4 |

1800

|

8000 |

12200 |

2550 |

2150 |

7.8 |

55 |

7.5 |

|

18 |

10000 |

14200 |

9 |

75 |

7.5 |

|||

|

21.6 |

12000 |

16200 |

11.8 |

75 |

11 |

|||

|

25.2 |

14000 |

18200 |

14.2 |

75 |

11 |

|||

|

28.8 |

16000 |

20200 |

16.5 |

75 |

15 |

|||

|

30.6 |

18000 |

22200 |

18.8 |

90 |

15 |

|||

|

20 |

2000

|

10000 |

14200 |

2750 |

2150 |

11.5 |

75 |

11 |

|

24 |

12000 |

16200 |

13.2 |

75 |

15 |

|||

|

28 |

14000 |

18200 |

15.5 |

90 |

15 |

|||

|

30 |

15000 |

19200 |

16.5 |

90 |

15 |

|||

|

20 |

2500

|

8000 |

12200 |

3250 |

2250 |

11.5 |

55 |

11 |

|

25 |

10000 |

14200 |

13.5 |

75 |

15 |

|||

|

30 |

12000 |

16200 |

16.5 |

75 |

15 |

|||

|

35 |

14000 |

18200 |

20.0 |

75 |

18.5 |

|||

|

40 |

16000 |

20200 |

23.5 |

110 |

18.5 |

|||

|

30 |

3000

|

10000 |

14200 |

3750 |

2250 |

16.5 |

90 |

15 |

|

36 |

12000 |

16200 |

20.5 |

90 |

15 |

|||

|

42 |

14000 |

18500 |

25.0 |

110 |

18.5 |

|||

|

48 |

16000 |

20500 |

31.0 |

110 |

18.5 |

|||

|

54 |

18000 |

22500 |

39.0 |

132 |

22 |

|||

|

60 |

20000 |

24200 |

45.0 |

132 |

22 |

|||

|

35 |

3200

|

10000 |

14200 |

4250 |

2450 |

20.0 |

90 |

15 |

|

60 |

18750 |

22950 |

45.0 |

132 |

22 |

|||

|

67.2 |

21000 |

25200 |

48.0 |

160 |

30 |

|||

|

80 |

25000 |

29200 |

68.2 |

220 |

45 |

|||

|

48 |

4000

|

12000 |

16200 |

4750 |

2450 |

31.5 |

110 |

18.5 |

|

56 |

14000 |

18200 |

42.8 |

110 |

18.5 |

|||

|

64 |

16000 |

20200 |

48.6 |

132 |

22 |

|||

|

90 |

4500

|

20000 |

29727 |

6941 |

3920 |

80.0 |

250 |

45 |

|

120 |

26667 |

36394 |

105.0 |

355 |

55 |

Related Products

INQUIRY